BENEFITS & INNOVATION

5 STEPS TO PERFECTION

We solve the complex requirements for your packaging:

Reducing costs, sustainability & absolute transport safety.

Our solution:

- Innovative, patented packaging solutions

- Fast, efficient test processes thanks to our in-house Ista test laboratory

No matter how complex: we solve your specific requirements so that you benefit from reduced costs thanks to state-of-the-art production technology and the most innovative packaging solutions.

5 STEPS TO PERFECTION - THE CUSTOMER JOURNEY AT TRICOR

IN-HOUSE INDUSTRY EXPERTISE

1. CUSTOMER CENTRE

In our Customer Center, we show you innovative solutions that we can offer you and assemble your personal team of industry experts and developers.

Whether Octabins, large load carriers or small load carriers, one to three-layer corrugated cardboard, EPP or multi-material solutions - we will identify the right packaging for your business.

COMPREHENSIVE NEEDS ANALYSIS

2. CUSTOMER ROOM

In the Customer Room, we discuss and analyze your specific requirements - in person at our premises or virtually.

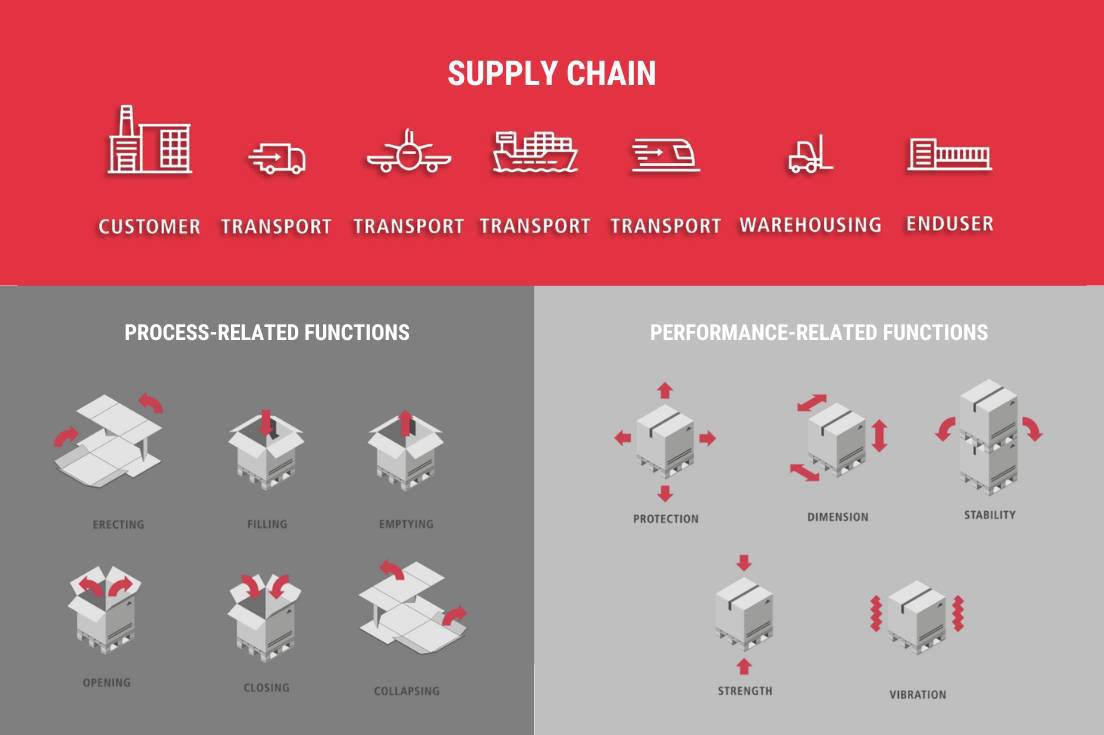

SUPPLY CHAIN ANALYSIS

3. COLLABORATION ROOM

Our Goal: Reduce the cost and risk to your products. In our Collaboration Room we analyze every step of your supply chain. From the your sites, to your end customer, then recycling of the packaging.

The Result: We know exactly where we need to start to develop the most efficient, sustainable and safe packaging solution.

PACKAGING DEVELOPMENT

4. DESIGN & INNOVATION CENTRE

More than 40 industry experts take over here. Designers, developers and packaging experts use state-of-the-art software and technology to evaluate the insights of your supply chain.

We then use a cost-efficient standard process to create prototypes for testing all climate and transportation conditions.

Your optimal packaging solution is created in the shortest possible time in our Design & Innovation Centre.

ISTA®-CERTIFIED PACKAGING TESTING

5. PROOF OF CONCEPT CENTRE

We don't waste any time. If you agree with the packaging design, we can put the packaging through its paces within 24 hours.

Our Proof of Concept Centre is an ISTA-certified testing laboratory that validates your entire supply chain in-house.

EXTENSIVE MANUFACTURING EXPERTISE

IN-HOUSE PRODUCTION FOR HEAVY-DUTY CORRUGATED BOARD

FASTER DELIVERY TIMES

With our in-house heavy-duty corrugated board production, we ensure the highest quality and flexibility for our customers. In-house production enables us to respond to specific requirements, minimize delivery times and guarantee sustainable production.

IN-HOUSE PALLET PRODUCTION

INDEPENDENT OF PALLET SUPPLIERS

An in-house, fully automated pallet manufacturing service enables us to produce customized disposable pallets according to individual specifications and in all sizes.

By developing and manufacturing our pallets for kit packaging ourselves, we are independent of external suppliers. This not only enables us to meet the highest quality standards, but also ensures smooth and fast production of kit packaging.

REUSABLE & MOLDED PARTS

EPP PRODUCTION SITE IN VIERNHEIM

In Viernheim, we have an entire site that focuses exclusively on the production of EPP and the manufacture of EPP packaging and molded parts.

EPP packaging and EPP molded parts can be varied in density, shape and elasticity according to your individual product requirements. Outstanding thermal properties, light weight and optional ESD protection ensure that they can be used across many different industries.

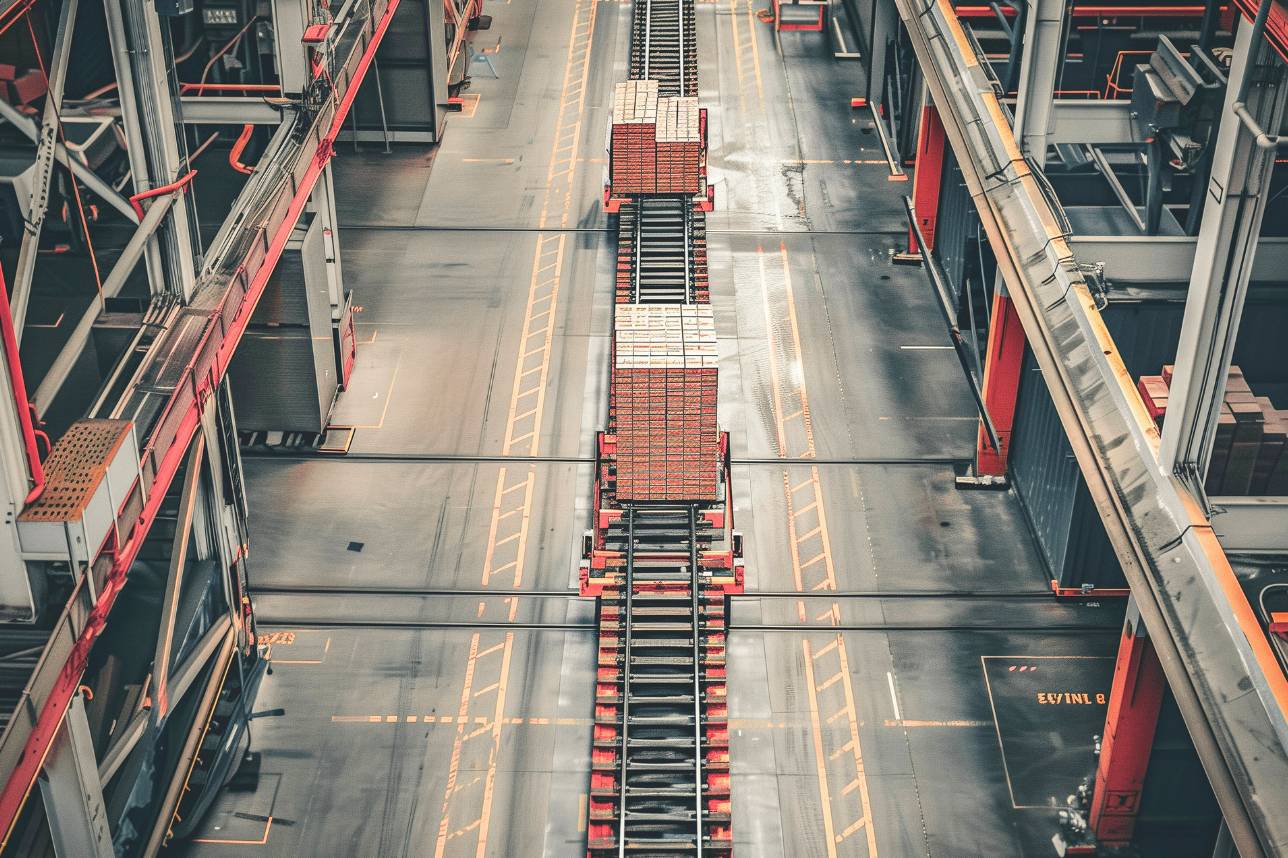

JUST-IN TIME & JUST-IN-SEQUENCE

WE ARE THERE FOR YOU

We have numerous assembly sites and logistics hubs in your area that enable just-in-time and just-in-sequence production.

CUSTOM SERVICES

PACKAGING SERVICES

PACKAGING SERVICES

We reduce complexity through intelligent logistics and co-packing along the supply chain.

We tailor our packaging services to you and your products. We design our packaging services to match your individual requirements profile:

- at your plant

- at one of our locations

- in a separate property

RELIABLE LOGISTICS SOLUTIONS

IN-HOUSE SHIPPING

FLEXIBLE FROM A TO Z

As a subsidiary of TRICOR Packaging & Logistics AG, TRANSCOR Logistics GmbH & Co. KG is our dedicated logistics service provider with market-leading performance.

Our extensive fleet, consisting of 200 jumbo trucks and e-trucks, enables us to offer first-class and low-emission full-service transportation services throughout Europe.

OWN ENGINEERING COMPANY

DEVELOPMENT & PRODUCTION

ROBOTIZED IN-HOUSE ASSEMBLY & PRODUCTION LINES

With our expertise in the development and manufacture of fully robotized in-house assembly and production lines for special packaging, we set new standards in efficiency and precision. Thanks to state-of-the-art automation technologies, we can implement individual requirements flexibly and reliably. This enables us to guarantee the highest quality, short response times and cost efficiency.