EVOPACK and TRICOR redefine sustainability and product protection in packaging

Bag-in-box packaging for liquid goods

Bad Wörishofen, Ahaus 25.03.2025

- 100 percent biocide-free - liquid goods safely packaged

- Up to 90 percent reduction in waste, transportation and storage volume

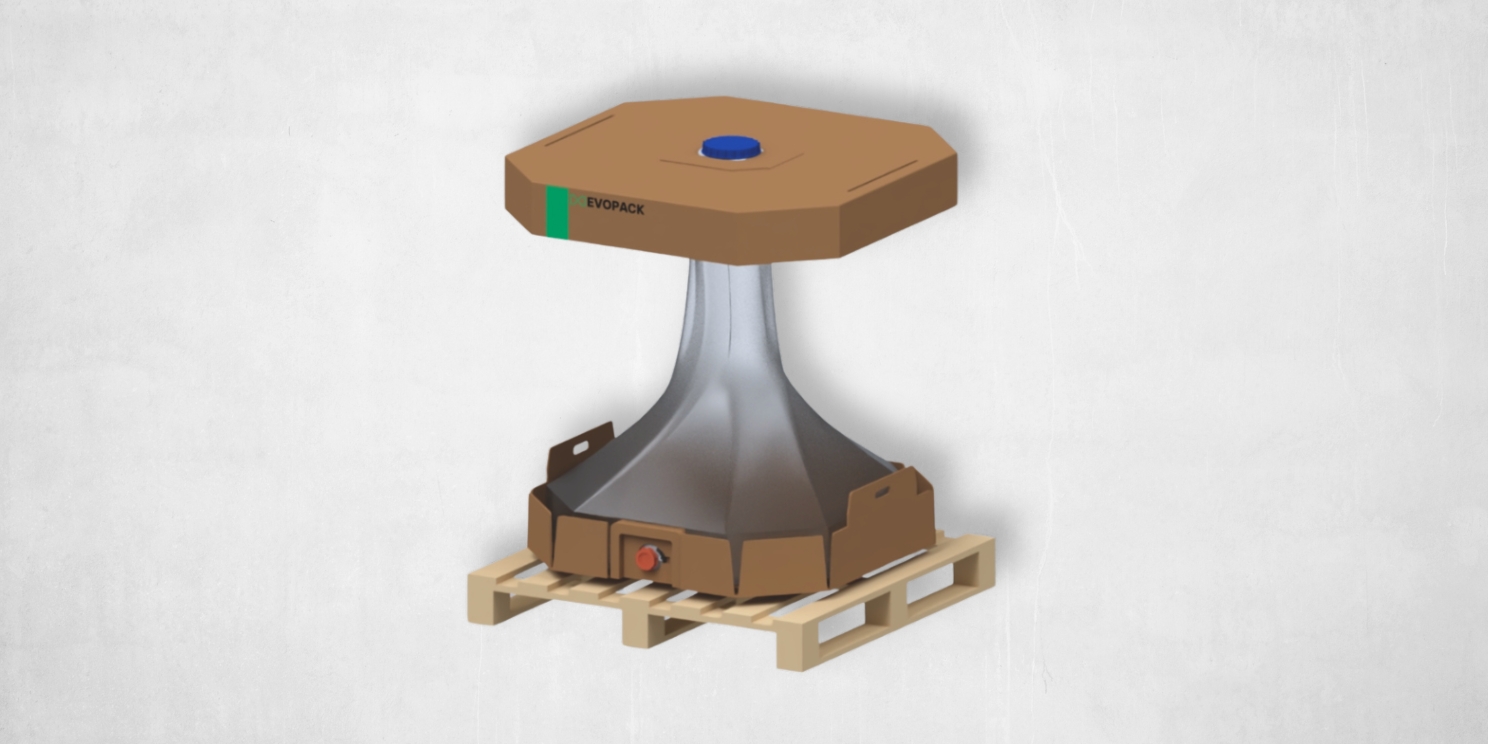

TRICOR Group, the leading specialist for innovative industrial packaging solutions, is launching an innovative bag-in-box solution with its cooperation partner EVOPACK that is specially tailored to the needs of liquid goods. The German start-up EVOPACK, which specializes in the development of innovative packaging solutions for the chemical industry, and TRICOR, the European market leader for industrial packaging, are thus setting new standards. The combination of EVOPACK's Boxli® 1000 and TRICOR's Quick Bin 2.2.4 significantly outperforms conventional solutions in terms of product protection, compliance, recyclability, CO2 emissions and supply chain efficiency and offers numerous industries a sustainable and high-performance packaging solution for 1,000 liters of liquid.

Requirements for packaging for liquid goods

This is because companies that manufacture chemical or liquid products have the highest requirements for packaging solutions. In addition to shelf life and product protection, legal regulations such as the Biocide Regulation, the Packaging and Packaging Waste Regulation (PPWR) and sustainability must be taken into account without compromising the cost-effectiveness of the product.

Cost-effectiveness and compliance reduce costs by up to 30 percent

This is precisely where the two solutions from EVOPACK and TRICOR come in. With the patented Boxli® lid module system, the integrated liner unfolds automatically when it is dropped and at the same time positions itself optimally in the octagonal Quick Bin 2.2.4 from TRICOR. The combination of the patented automatic base with the patented lid module system ensures that the bin is ready for filling within one minute. However, this is not the only advantage of the product, which comparable other solutions only achieve in 5 - 10 minutes. Thanks to the octagonal shape with long sides, the filling volume can be optimally utilized. As a result, the container remains below a height of 1.2 m despite the 1,000 l volume.

“Particularly in light of the fact that logistics costs have risen by up to 50 percent in the last five years, transport, storage and waste volumes are important arguments for profitability,” emphasizes Philipp Kosloh, CEO of the TRICOR Group.

The packaging is delivered flat-packed, is easy to handle and can be assembled into a secure 1,000 l package for liquid products within a minute. This reduces the empty transport volume and logistics costs by over 300 percent. The packaging is then assembled in CP3 pallet format.

Boxli® 1.000 biocide-free and still offers maximum product protection

The form-fit or 3D liner adapts perfectly to the shape of the packaging when filling and contracts when emptying. This design prevents a “headspace” from forming. What acts as an oxygen barrier ensures that the contents are protected from a reaction with air and oxygen right down to the last drop. This enables a reliable shelf life for the products without biocides that are harmful to the environment and health. The packaging achieves maximum stability thanks to two 3-wall Quick Bins, one inside the other.

Sustainable and PPWR compliant

Nowadays, packaging solutions have to be considered holistically. Boxli® 1.000 from EVOPACK and TRICOR does just that. In addition to high economic efficiency and product protection, aspects such as the elimination of recycling lead to a 50 percent reduction in CO2 emissions. The majority of the packaging is corrugated cardboard, which can be returned to the material cycle worldwide - eliminating problems when exporting to other countries. The plastic content is around 2.3 kg and is being consistently reduced further. The inliner is 100% recyclable and in most cases made of pure PE material.

“Our packaging is completely recyclable and meets the requirements of the PPWR. Overall, compared to other rigid plastic packaging, 90 percent waste volume, 80 percent plastic and an average of 70 percent biocide quantity can be saved, in some cases even 100 percent,” says Timo Geiger, founder and Managing Director at EVOPACK.

The elimination of the rinsing process with less water and detergent consumption also contributes to the sustainability of the container.

“Our development experts have put the packaging through its paces in our ISTA-certified test laboratory in extensive rolling, stacking and logistics tests. This allows us to offer customers from industries such as chemicals, food, pharmaceuticals, ceramics, oil, textiles and leather a safe solution with ecological and economic benefits,” adds Philipp Kosloh, CEO of the TRICOR Group.

About TRICOR

The TRICOR Group has been part of the globally active Rengo/Tri-Wall Group from Japan since 2019. The specialist for industrial packaging solutions offers its customers a wide range of sustainable packaging and individual multi-material systems. With its in-house logistics specialist TRANSCOR and its 200 vehicles, the company impresses its customers with the fastest, Europe-wide transportation services. This unique service portfolio makes the TRICOR Group a leading European partner for industrial companies in the automotive, chemical, frozen food, electronics, renewable energy, mechanical engineering, medical and measurement and control technology sectors. The company, based in Bad Wörishofen (Bavaria), employs around 2,100 people at 17 locations in Germany, the Czech Republic and Slovenia.

About EVOPACK

EVOPACK is a packaging start-up from Germany that has made it its mission to protect aqueous products through “plant hygiene, product formulation and packaging instead of biocides”. Since 2025, EVOPACK GmbH has been 25 percent owned by RINGMETALL SE, where it is part of the IPL (Industrial Packaging Liner) division. With an annual turnover of around 90 million in the field of liners for liquids and bulk goods, RINGMETALL SE is the leader in the European market. EVOPACK's aim is to be as close to the customer as possible and to offer complete solutions in the packaging sector for liquids or to develop them together with customers. The topic of hygiene also plays an important role here, where support is provided at the customer's premises to help reduce biocide quantities.

Press contact TRICOR Group: Dagmar Ginzel

Tel.: +49 171 50 58 296

[email protected]

Press contact EVOPACK: Timo Geiger

Tel.: +41 76 746 3355

[email protected]

Press material

Photo #1 / Photo #2 /Photo #3 Photo credits: TRICOR Group

PDF: Download press release